A company in the aerospace industry was nearing the finish line on a critical assembly project when an unexpected quality issue threatened to put their timeline in jeopardy. A small but geometrically complex contact with deep inside diameters required tight tolerance plating. Several trial barrel and vibratory plating runs at their usual vendor revealed uneven thickness, poor ID coverage, and nesting issues that were causing parts to nest together.

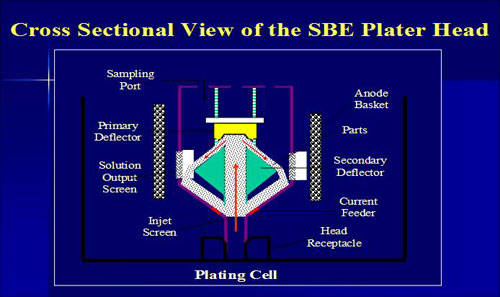

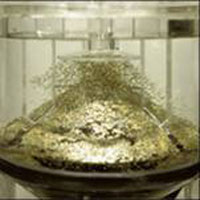

At Electro-Spec, we are a recognized innovator in the plating industry, which is why this company approached us seeking a solution to this issue that was threatening the integrity and timeline of the project. After reviewing the print, we recommended using our SBE (Spouted Bed Electrode) process, ideal for small parts with difficult geometry. Solution is continually replenished in the chamber and constantly surrounds the parts with fresh plating electrolyte, which ensured tightly controlled and uniform coverage on the OD and ID, Ultrasonic movement of the components through the fluid also served to keep them separate and prevented them from nesting together during the plating process.

By using this process, we were able to successfully plate the contacts and satisfy the customer expectations regarding coverage and uniformity, especially in the deep IDs. They quickly contracted with us to implement this process across several different part numbers with the same quality and acceptance criteria.

If you are interested in more details about this project or the processes we used to complete it, contact us today.